Products

Flexible Innovative Solutions for Safety-Critical Applications

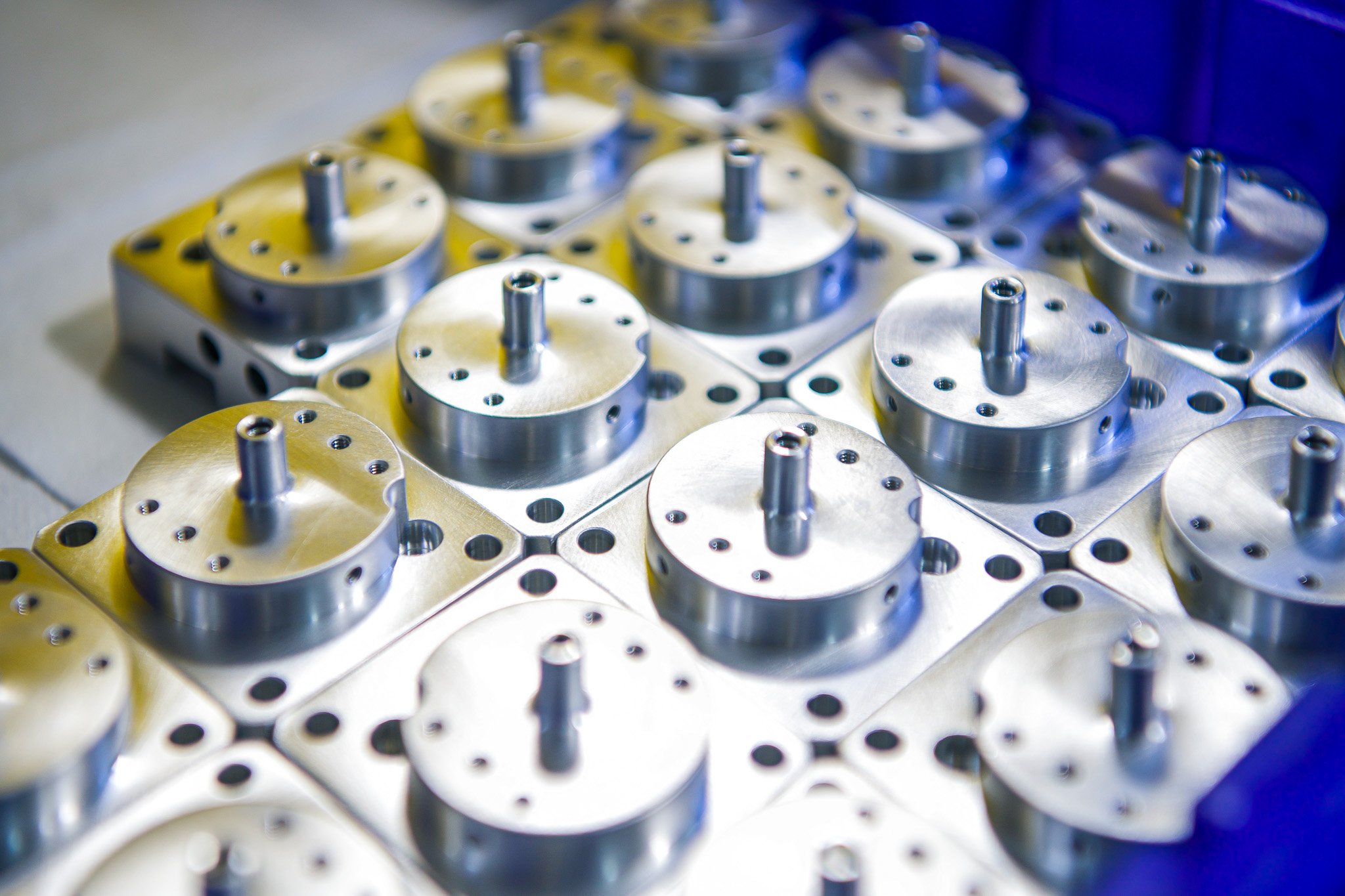

We deliver precision.

From initial design to qualification to aftersales service, we achieve the competitive price, performance, and quality levels aerospace leaders require. We’re the preferred supplier of servo valves anywhere on airplanes, helicopters, and business jets where robust design is required for high-temperature and high-vibration applications quality levels civil and military leaders require.

-

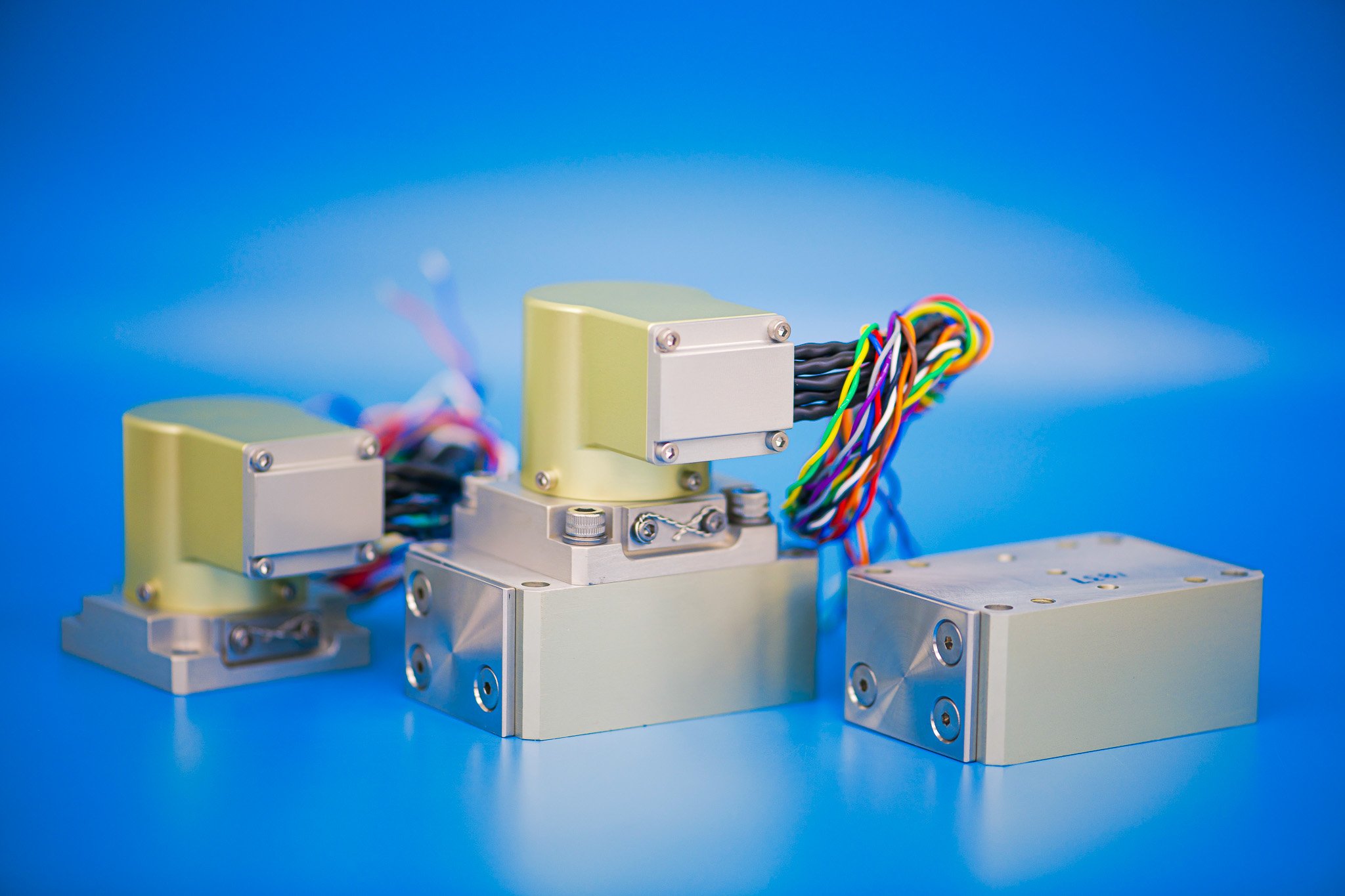

Single Stage Servo Valves

-

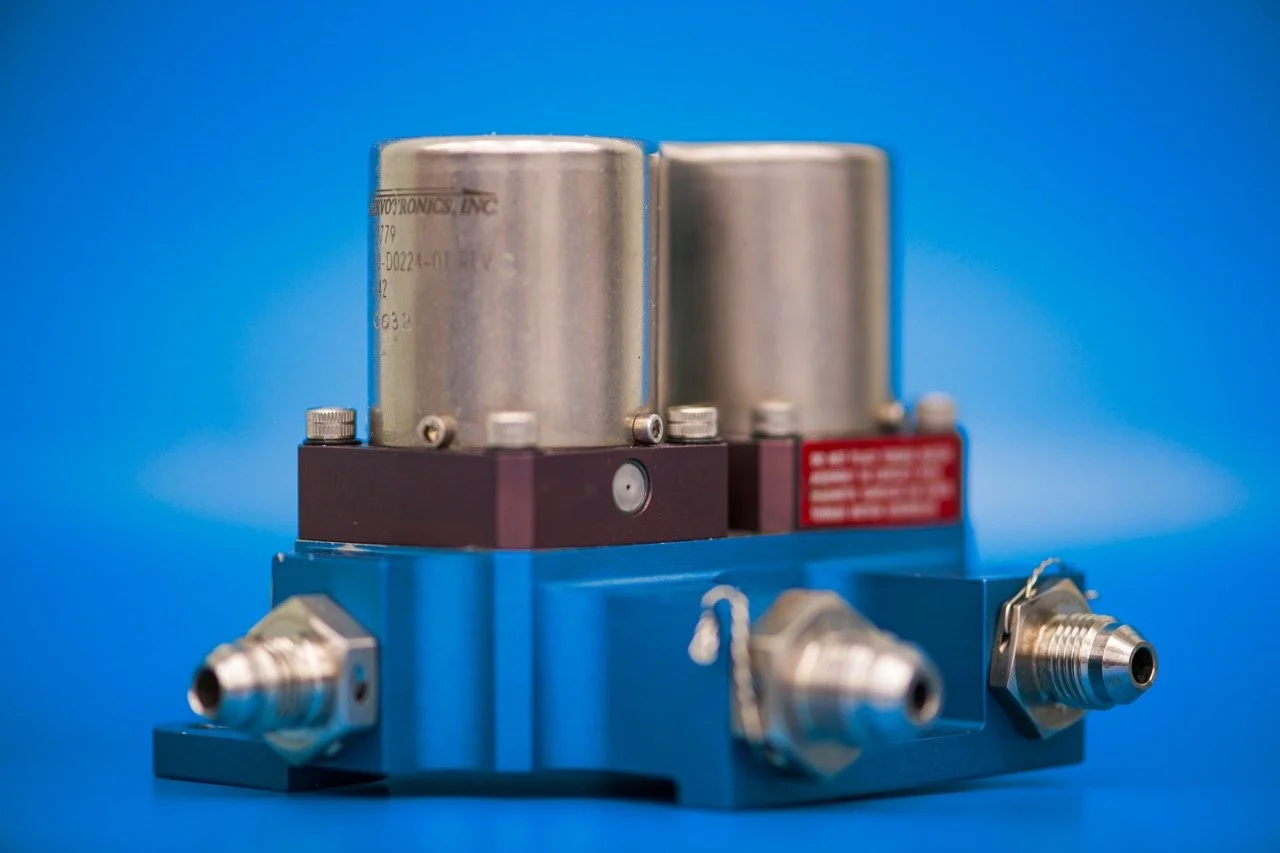

Two-Stage Servo Valves

Electro-hydraulic & Pneumatic Servo Valve Technology

Servotronics specializes in meeting the performance, quality, and commercial specifications of our aerospace customers with our premier single and two-stage servo valves. Our electro-hydraulic and pneumatic technology is proven in a range of safety-critical applications:

Trusted

Single & Two-Stage

Servo Valves

System

Fuel

Hydraulic

Pneumatic

Architecture

Nozzle Flapper

Shear Orifice (Clevis)

Jet Pipe

Functionality

Proportional Control

Two Position Control

Displacement Torque Motors

Servotronics Products

Our products yield industry-leading performance in high-temperature and high-vibration applications, and are contamination resistant without requiring damping fluid.

Core Capabilities

Operating Temps:

-65 to 450˚F (-54 to 232˚C)

Power:

1.2 in lbs torque (0.14 Nm)

Encapsulated Design:

1500 vac dielectric and 500 vdc insulation

Coil limiting factors:

Up to 4

Dissipation: Up to 7 watts

Rated Current: Up to +/-300 mA

Resistance: 10-1200 Ω

Pressures

Operating:

5 to 3500 psig (241 bar)

Proof:

Up to 5000 psig (345 bar)

Burst:

Up to 8000 psig (552 bar)

Performance

Vibration:

Up to 100 G (20-4000 Hz)

Hysteresis:

<2% rated current

Threshold:

<0.5% rated current

Our focus is on your requirements.

If your project requires servo valve precision, we partner with you to optimize a cost-effective solution. We take a different approach than catalog suppliers and work collaboratively with our customers’ engineers to precisely configure our flexible building blocks to meet your specifications.

Are you ready to get started?

Submit a Request for Information or Request for Quote